It is also call frosted glass、Dark Glass.It used normal flot glass made by Mechanical blasting and Manual grinding or hydrofluoric acid dissolution. As the surface roughness, so that produce diffuse light, transmittance without perspective, it can be soft indoor light but not glaring.Commonly used in the need for hidden bathroom, toilet, office doors, windows and partitions. Should be used with the hair out of the window-oriented.

With ground-glass film is set in order to ensure that ground-glass cylinder with a closer contact.Because the set of cylinders is also a frosted bottle, and with ground-glass usually also apply this frosted side. This is not easy to collect the gas leak had.

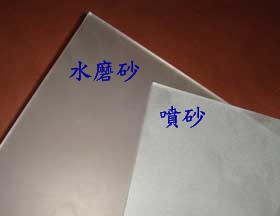

Most of the early use of sandblasting glass, frosted glass technology, is a very common and economic processing of glass, the use of high-pressure air jet to contain corundum glass surface damage and the resulting fog effects, can be used for any glass surface, there are also commonly used in other materials on, such as metal, aluminum, wood and so on, is to use very wide areas of glass processing techniques.

![]() After blasting the glass surface, but the maintenance is not easy, in particular, are most afraid of contaminated water or fingerprints, grease and other substances, and difficult to clean. And the water for production of ground-glass frosted in the delicate touch on the degree and much better than blasting glass.

After blasting the glass surface, but the maintenance is not easy, in particular, are most afraid of contaminated water or fingerprints, grease and other substances, and difficult to clean. And the water for production of ground-glass frosted in the delicate touch on the degree and much better than blasting glass.

|

|

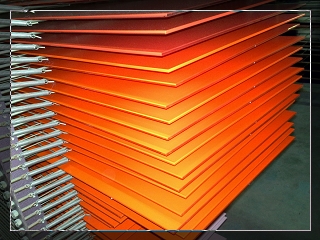

Selection of gloss paint glass is particularly good light version of the glass, after a special treatment, drilling, milling, a opacity ... and other features,

Thickness of 3 ~ 12m / m Maximum size: 144 "X96" (the original plate glass paint-related material safety data sheet download)

|

|

|

|

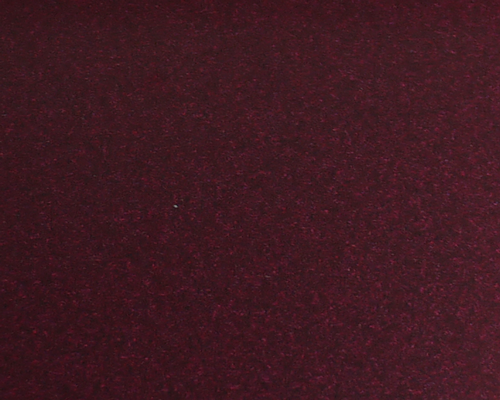

Rainbow Glass Metallic Paint: |

|||

|

|

|

|

| A01 | A02 | A03 | A04 |

|

|

|

|

| A05 | A06 | A07 | A08 |

|

|

|

|

| A10 | A11 | A12 | A13 |

Rainbow Paint Glass in general color: |

|||

|

|

|

|

| U WHITE | B01 | B03 | B06 |

|

|

||

| B07 | B08 | ||

3D of the original plate glass baking: |

|||

|

|

|

|

| D01 | D02 | D03 | D04 |

|

|

|

|

| D05 | D06 | D07 | D08 |

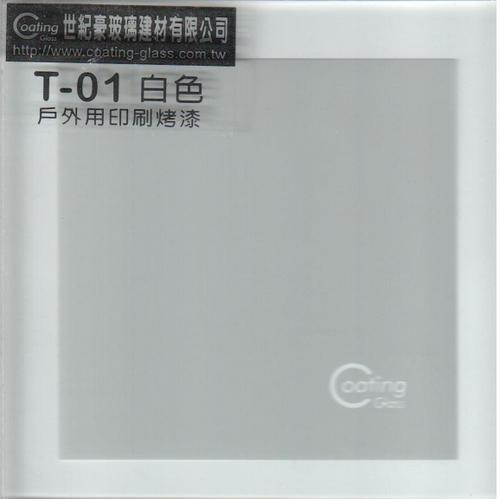

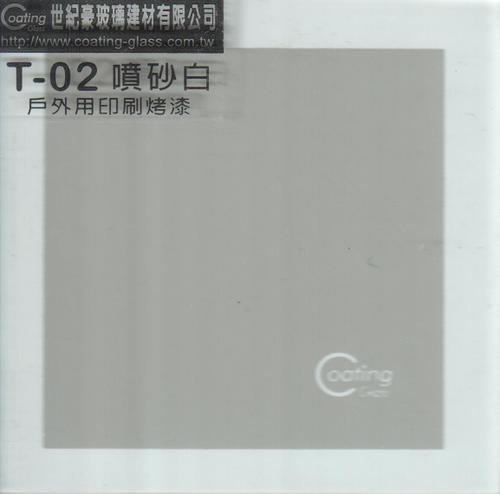

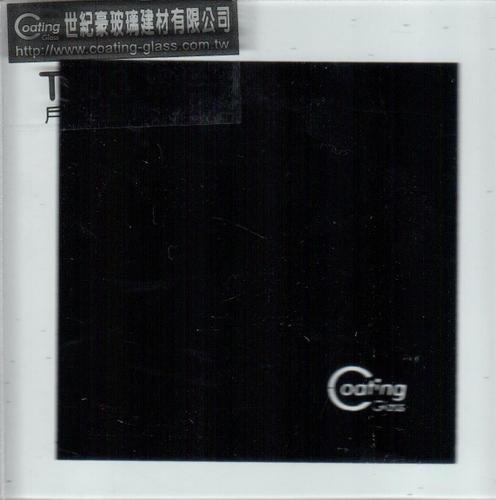

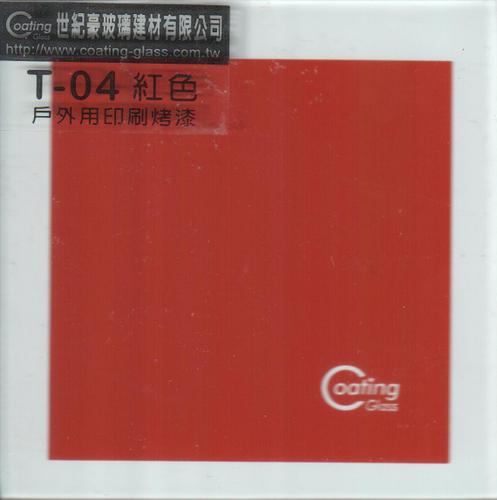

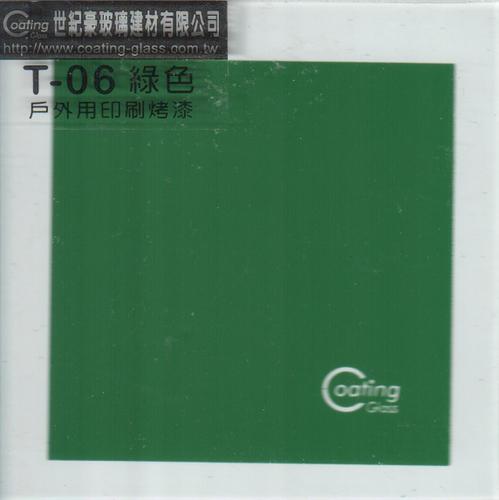

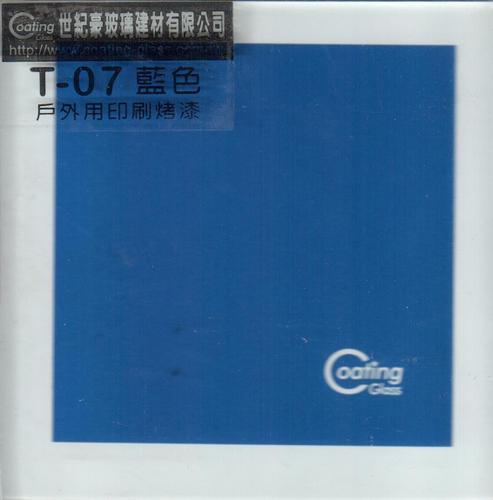

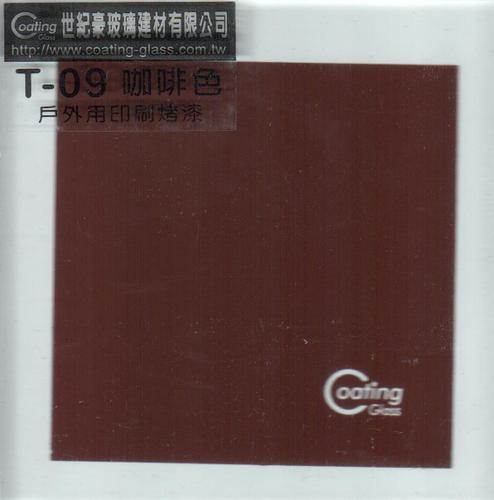

| OUTDOOR PRINT COLOR GLASS: | |||

|

|

|

|

| T01 | T02 | T03 | T04 |

|

|

|

|

| T05 | T06 | T07 | T08 |

|

|

||

| T09 | T10 | ||

| Glass paint application examples: | |

|

|

|

|

| Export packing glass baking: | |

|

|

|

|

|

|

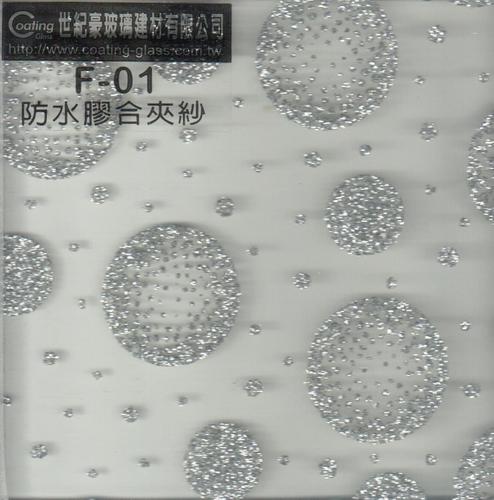

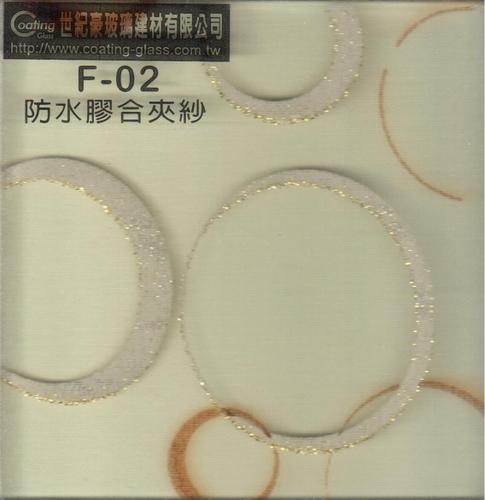

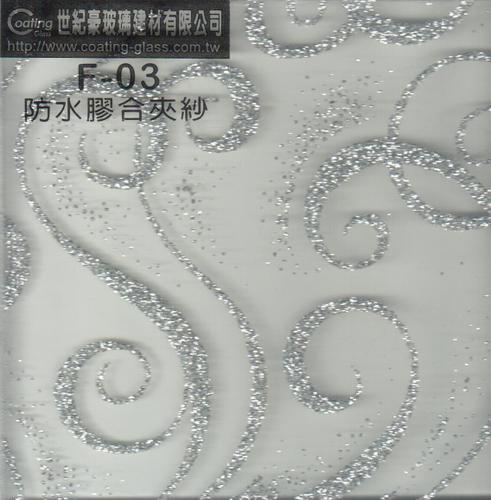

Applications::

Interior partitions, bathroom dry separation of occasions that require security.

Production::

|

|

|

|

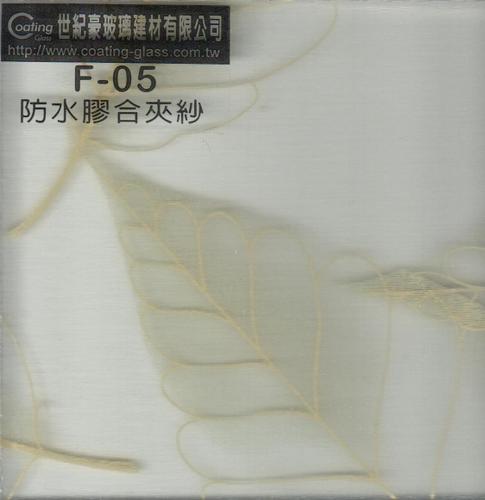

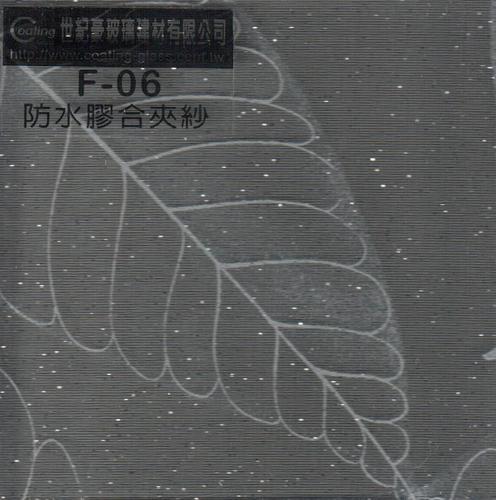

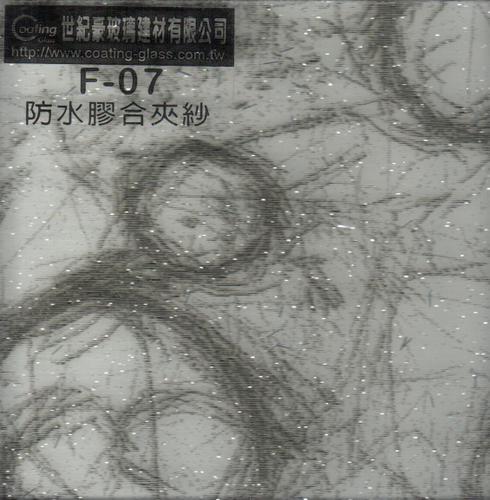

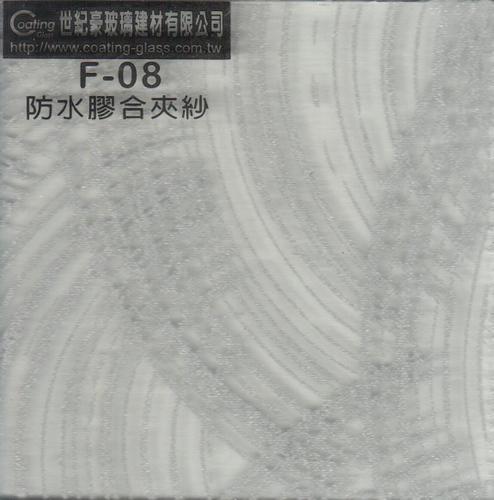

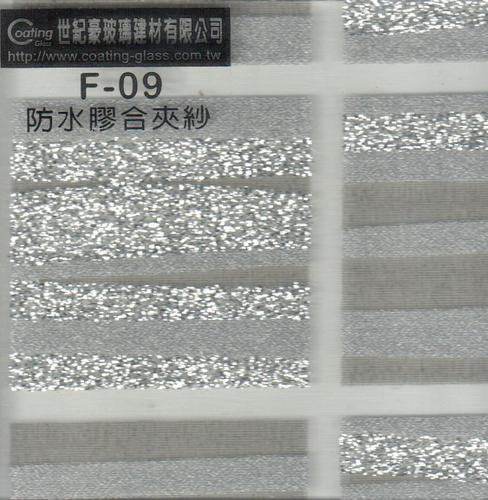

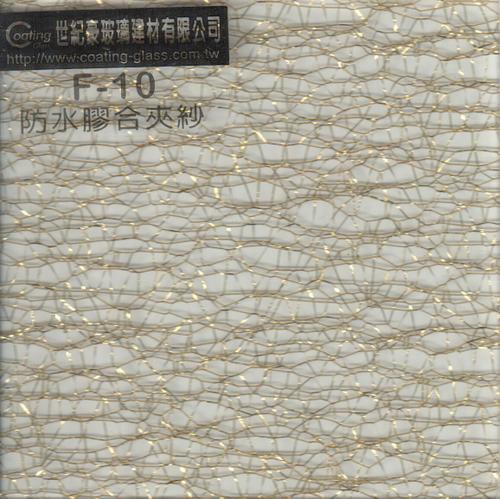

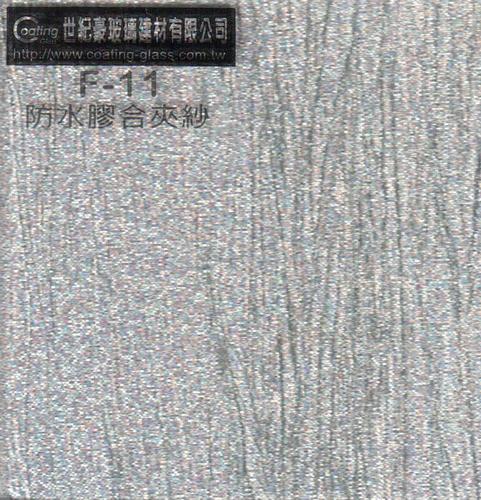

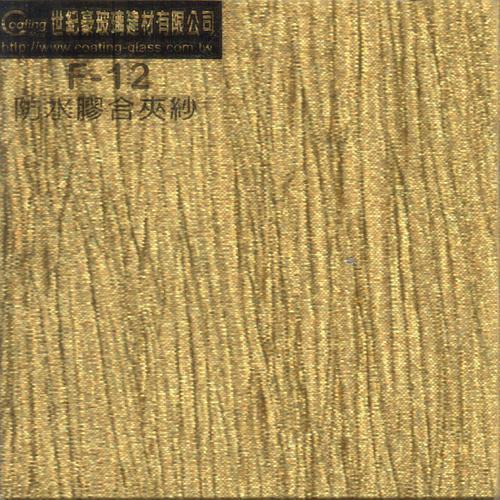

| F01 | F02 | F03 | F05 |

|

|

|

|

| F06 | F07 | F08 | F09 |

|

|

|

|

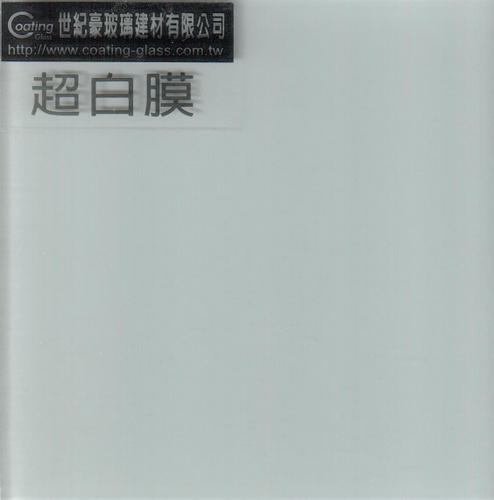

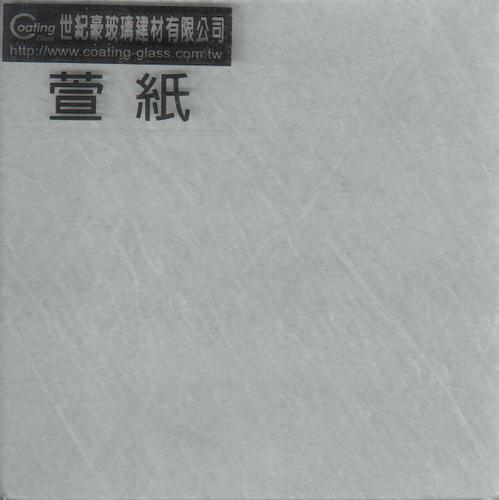

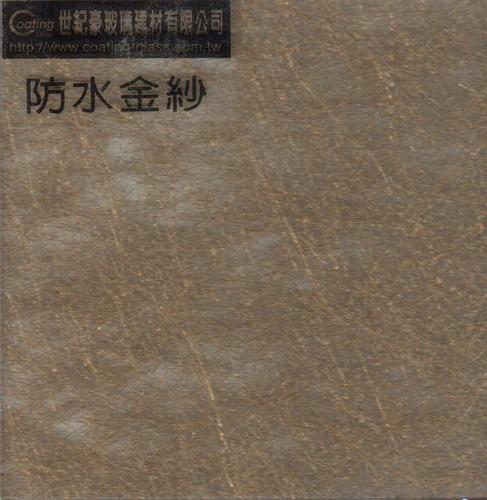

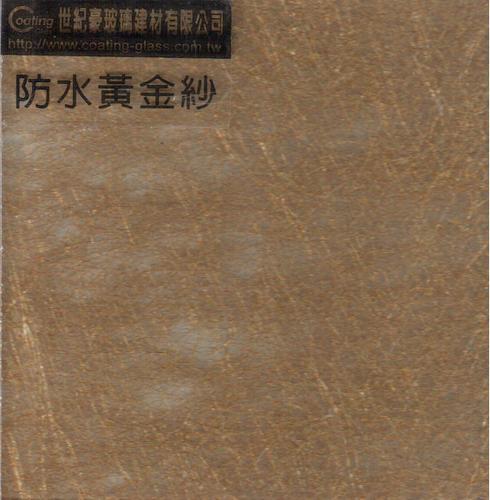

| F10 | F11 | F12 | 超白膜 |

|

|

|

|

| 宣紙 | 防水金紗 | 防水黃金紗 | 防水銀紗 |

Mirror glass system with a smooth surface of the floating plate glass in his back plated with silver film, copper film, as well as the two-story water-proof protection of paint and other triple-processing procedures are made.

Benefits:

Image clarity, precision.

Back paint acid and moisture.

Applications:

Construction, decoration, furniture.

Automobile rear-view mirror.

Specification:

Depth:1.3-6mm.

Max Size:96” x 144” (2438mm x 3658mm).

Security mirror plate foil

Depth:1.3-6mm

Max Size:48” x 144” (1219mm x 3658mm)

| Specification | ||

| Kind | Depth(mm) | Size(In.) |

| Edged Glass | 1.3 | 73x75 |

| 1.5 | 73x75 | |

| 2 | 60x84 | |

| 3 | 84x120 | |

| 4 | 96x144 | |

| 5 | 96x144 | |

| 6 | 96x144 | |

|

|

|

|

| Mirror | Brown Mirror | Light gray Mirror | Black Mirror |

|

|

|

|

| Jade Mirror | Fine white Mirror | Blue Mirror |

|

Ultra Clear Glass: Kind: Specification: 5mm 243 x 330、6mm 200 x 321、8mm 225 x 321、10mm 225 x 321、12mm 225x321(公分)。 General optical glass will be shown with a green color, thus affecting the texture originally wanted to showcase the goods, or when there is color of the glass processing will destroy the glass when it is thought the color rendering, only select ultra-white glass will be able to fully demonstrate goods or color gloss. |

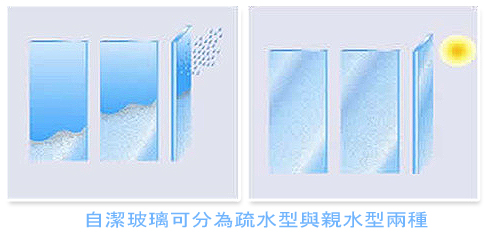

- Self-cleaning glass, anti-pollution raw materials of glass, the glass produced in Taiwan. The company grinding process → cutting → → → drill holes → enhanced self-cleaning glass surface anti-fouling coating bath → → finished curing operations.

- The company produces self-cleaning glass can be divided into two kinds of hydrophobic and hydrophilic, in which hydrophobic self-cleaning principle is that the hydrophobic layer by a low surface energy properties, so that the surface contaminants is not easy attachments with anti-fingerprint and anti-oil, the effectiveness of waterproof stain (contact surface is greater than 110 °) for indoor use.The hydrophilic form of self-cleaning nano-photocatalyst in sunlight (UV) irradiation to produce free radicals, which produce free radicals destroy the molecular structure of self-cleaning, so when the next heavy rain will be easy to remove stains (contact angle of small at 5 °). In order to achieve the anti-fouling effect of the product itself, we must measure the use of the environment and needs, and then select the combination of the self-cleaning glass.

Benefits:

|

||||

Applications:

|

|

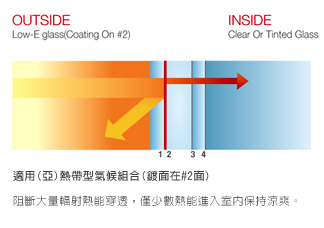

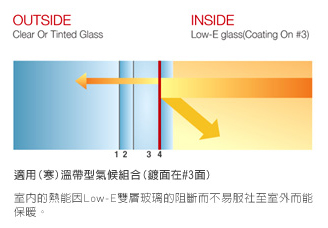

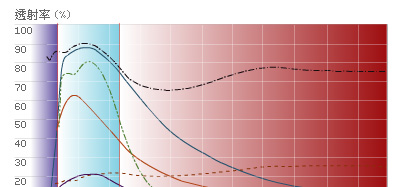

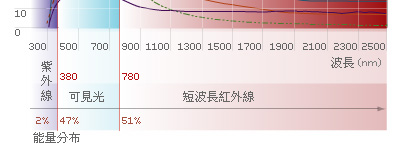

|

Low-E Glass(Low Emissivity Class): It iss a thermal spray coating method or through a vacuum sputtering method on glass surfaces coated with single or multi-layer metal, alloy or metal oxide made of glass products.In the sputtering process, its surface will result in a total structure of metal and dielectric thin-film-like metal layer.In general the energy of sunlight, infrared heat holds about 51.2%, visible light occupies about 46.8% of the heat, ultraviolet and other rays occupy about 2%。Mainly through the metal dielectric film surface to block the energy of sunlight into the infrared and ultraviolet light, while in the visible region 380nm ~ 760nm barrier rate is very small, from lighting to ensure a good glass of . By blocking access to the indoor heat so as to achieve the purpose of reducing indoor air conditioning energy consumption.Accompanied by significant reduction in UV transmittance, but also greatly increased the buildings comfort. The traditional coating glass and colored glass are mainly based on reflection and absorption of visible light.In other words, LOW-E coating layer on the visible light transmittance as high as 80%, but the surface of metal elements will be reflected visible light, the main factor in the far-infrared thermal conductivity, reflectivity of 70% ~ 90%. This makes comparison with common glass and its optical performance is greatly improved, but are also addressing past performance and light insulation properties of contradiction,LOW-E glass used in building houses the majority of the general doors and windows, skylights, floor to ceiling windows, aluminum windows and doors, airtight windows and curtain windows, etc., while the industry used in all kinds of sun visor, are received with great results. LOW-E Glass can be divided into the following two kinds of: 1.Online Low-E glass coating(Hard Low-E Glass)Recoverable monolithic, glued-style, double-layer-type combination, and can be directly enhanced high-temperature, bending processing, use very convenient.Its manufacturing method is to use the main pyrolysis process(Pyrolytic process), In the glass leaving the furnace, will be Low-E film material sprayed on the flat glass forming temperature, using thermal decomposition process will film material coated on the plate glass,,Such ways of dealing with Low-E coating and glass manufacturing process connection, also known as on-line (On-Line) LOW-E coating.2.Off-coated Low-E glass(Soft Low-E Glass),For coating metal layer does not have a high temperature, can easily result in oxidation of the phenomenon is not suited to long exposure to air, but its excellent thermal insulation effect is to produce a complex layer of glass of a good choice. Its manufacturing method is to use the vacuum coating process(vacum process),At present most of the business community is on the plate glass with sputtering (sputtering) or magnetron sputtering (magnetron sputtering) Preparation of multi-layer metal or ceramic (metal oxide) film, also known as off-line (Off-Line) Low-E Coating.Soft and hard coated Low-E Glass Comparison Chart:

|

||||||||||||||||||||||||||||||||

The design of modern architecture is not only emphasizes the arts, luxury, and even avant-garde minimalism, or fashion, architectural design trends should be to adapt to local climate,Like Assembled House landscape or lighting in order to let the face of Xishai hand, the side windows are also great difficulties caused by the user. To be able to appropriate to meet the user immediate needs, and with the appropriate building materials, and to achieve sustainable energy conservation goals, this is the real balance of humanity and the professional green building design. |

|||||||||||||||||||||||||||||||||

Benefits: High-performance fire-resistant glass:In case of fire, when the glass surface heated to 120 ° C when the soda silicate layer on each floor will become thick and hard, opaque foam fog will not only block the spread of flame and smoke, and can block the radiant heat generated by fires. 。(Even in the 900 ~ 1000 ° C heat of fire burning, the temperature of the glass on the back in an hour can still be maintained at 140 ° C within the scope of;So close to room temperature or asylum channel can still control 50 ° C below the refuge not only easy, and will not be burnt. Relief workers can be a very ample use of the one-hour time will be stored in the room moving valuables safe)。 High-performance insulation of windows:As the multi-level of the glass and gel layer of the silicate soda mix, with a high degree of anti-sound,。High-Performance Security Features:Can withstand bullets, bombs and violent attacks against persons and property have a greater protective effect.High-performance safety glass:Department of laminated multi-layer composite made of glass, fire, high security.

A fire door for the kinds of (individual identified):Particularly suitable for a variety of buildings, walls, vestibule, stairs and walkways between the doors and windows。 |

|

|||

|

Covert observation of the need to monitor the local, spy glass, is to monitor, preserve and monitor the best choice. Plenty of room in the lighting, transparent mirror that looks like a mirror, but on the other hand it is common colored glass.

Peep at the glass surface by chemical vapor coating, resulting in durable surface. And transparent way mirror can be glued with other glass processing, increase the safety of glass,Reflective coating of the glass due to peep effect is very smooth, if the thermal processing (such as reinforced, bending, heat hardening, etc.) would likely lead to some changes could not reach the reflective optical effects in the formation of.

Peep glass, high reflectivity and high transmission rate, and the resulting effects can also clearly see both concealed the inspected area. Transparent mirror used in hospitals, supervision, observation room, police stations, in particular, space design, etc. 。

Note the use of peep Glass Design:

| Glass directional: |

| When installed, they must face a transparent mirror reflection light at the direction of the target being observed. |

| Lighting Types: |

| Been observed target the lighting should be evenly shines on the walls and furniture, not to light towards the glass, and the observer side of the light should be dim, and suggested an opaque shade. |

| Background Color: |

| Been observed target at a better color to bright, while the observer side of the color environment, as far as possible the same non-reflective, and bleak, and there fancy designs to minimize and avoid a contrast color. |

| Distance and brightness: |

| To be observed target office of the glass to maintain a certain distance (60 cm above), and the proposed measure of rate of 10:1 light was observed target at (10) Bright, the observer (1) dim. |

| The line of sight to a minimum penetration: |

| To be observed as far as possible objectives of Department and the lights farther away from the glass, in order to further reduce the line of sight transmittance, observers could be a party to deepen color glass 。 |

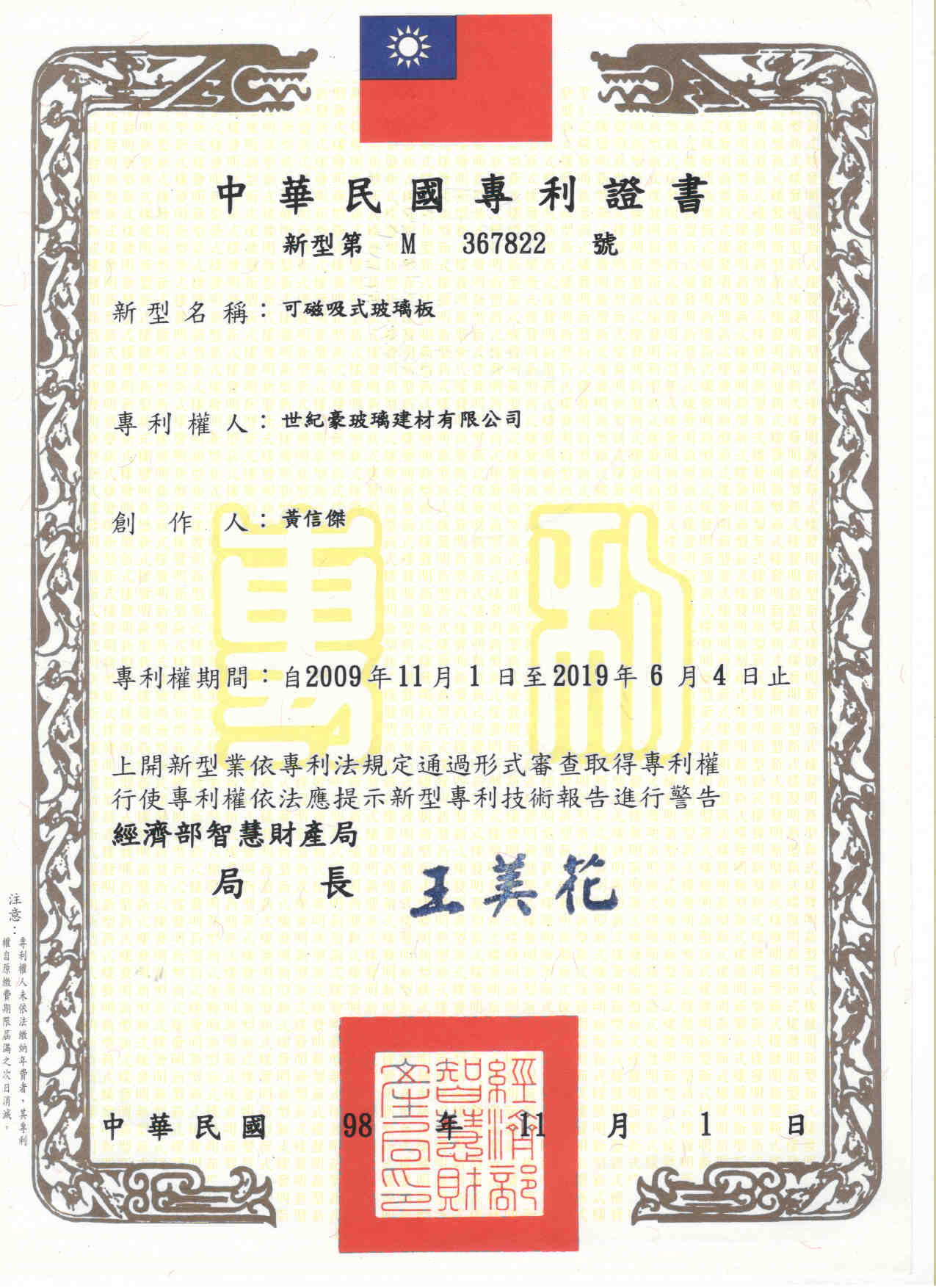

Magnetic Glass is a white version can be magnetic-type glass, its departments to a body as the base metal, the metal plates in their upper body with the majority of hooks on the back of the Department can be easily pre-set the hook hanging on the wall ,For more on the metal plate body of the end-fitting layers of glass, combined with a pre-printed pattern layer formation method, and the pattern layer of the main surface coated with a glue layer, and finally a layer of glass laminate solid in the glue layer,In order to form a group to provide hanging features a rich background with the color of the pattern layer may be layers of glass surface to water-based pen to pen or oily repeatable-type writing, graffiti creators.

|

| This product is an exclusive research and development by the Company, for purchase, please contact our sales office or the province. |

|