Tempered Glass

After forming in the manufacture of glass, due to handling, impact, scratches, water, gas and other role, will be produced on the surface of many human eye can not see the micro-cracks, so that makes the glass tensile strength decreased more than a hundred times.To solve this drawback, the scientists are the invention of glass, namely the use of rapid heating and then cooling the heat treatment method, making the glass surface of the compressive stress layer, in that the role of compressive stress layer, all the tiny cracks close together receive a high degree of oppression, Unless you exert tremendous power in order to crack open and break.

Bent Tempered GlassCurved architectural glass reinforced materials in the future appearance of the new building trend in the global market demand is growing rapidly.In response to the increasing appearance of the building of style and elegance of the curved shape of the demand for larger, Taibo Glassrobots Finnish companies in particular the introduction of a new generation of standards designed curved glass processing system, known as the "Rainbow maker" in the patent production equipment,Using ad hoc adjustments of bend radius control technology can be a special arc shape glass shapes, glass in the processing furnace heated by precise temperature control can be achieved by the correct processing temperature. This method can reduce the glass due to excessive heat generated is not the whole ripple to protect the excellent quality.

The strength of curved glass curved glass 3-5 times normal. Glass is not hanging around the four holes. Horizontal bending strengthened, the quality and stability. Temperature difference and thermal shock resistance to about 200 ℃ without rupture. Bump sides can reach the same good quality, especially in the case when applied to curved reflective glass, clear visual quality is even more evident.

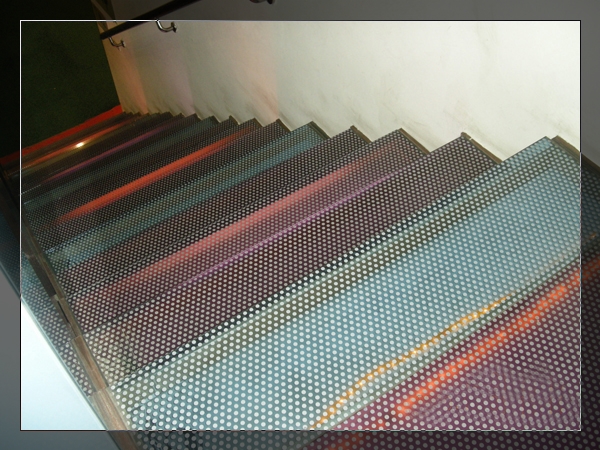

Can be processed into a Bent Double Tempered double glass. Wave type, curved glass curtain wall-type buildings. Such as: office buildings, shopping centers and airports, concert halls. Arc revolving door, landscape lift jacket. Curved stairs, handrails, skylights, access canopy, swing the stairs. Arc-shaped fish tank, display cabinets, furniture style. Arc office partitioning.

Thickness:5mm~19mm Max Size:3000mmX5000mm Min Size:220mmX430mm Arc Depth:500mm以下 Bending angle:1 / 4 circle the following |

|

Heat Soak TEST: Will strengthen the glass in the adventitious presence of nickel sulfide (NiS) impurities, in the holding temperature of the hot-dip strict control of the furnace , Due to nickel sulfide by high-temperature α-NiS is converted to low-temperature state of the β-NiS.Conversion will be accompanied by volume expansion of 2.4%, if its location just in tension layer, will be the first furnace in the hot-dip burst open, in order to; up to reduce the chances of glass blew after installation purposes. Benefits:

Specification: Glass thickness::3mm-25mm |

|

|

Laminate dGlass system using high temperature and pressure, in sandwiched between two pieces of glass into the robust and rich middle of thermoplastic resin films (FVB) and made. Benefits:

|

|

Double-glazing is the middle of two pieces of glass separated by dry air or inert gases such as argon and made. Particularly good insulation effect, is an ideal energy-saving building materials. Middle-tier system due to dry air, so there are anti-fog effect. If the charge into the argon and other inert gases, better insulation effect. Applications: Specification: Middle Distance:6mm, 8mm, 10mm, 12mm, 16mm Max Size:96" x 138" (2438mm x 3500mm) |

| Drill hole Processing | |

|

|

| Straight-line Processing | |

|

|

| Abnormity Processing | |

|

|

| Hypotenuse Processing | |

|

|

|

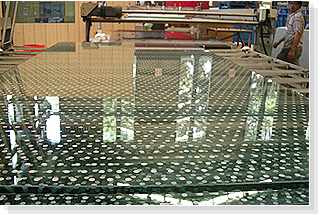

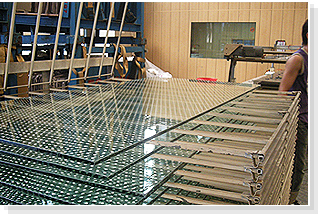

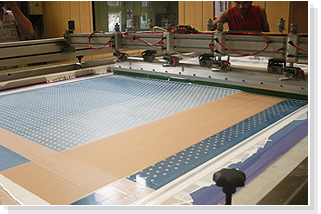

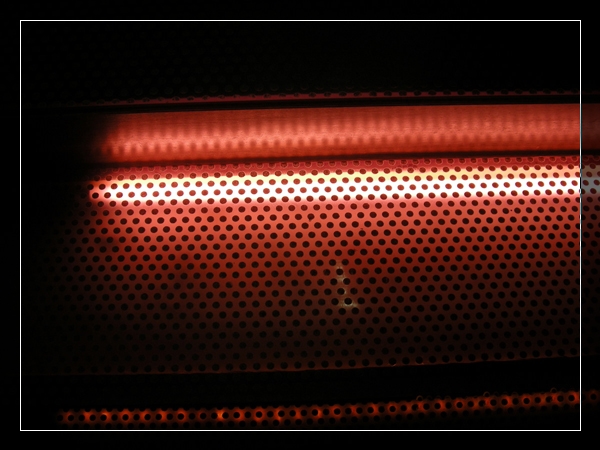

Screen Printing Glass is specially designed for ceramic paint stencil, the pattern printed Brush to the glass through the strengthening furnace 630 ℃ heat into the glass surface paints And made of stability does not fade, a variety of patterns change Screen Printing Glass. Benefits: Color diversity, patterns more choices: screen printing glass, a variety of colors and patterns can also be customized according to designers need to Patterns, creating a unique space design. Anti-glare: screen printing glass, due to local printing can reduce glare glass. Ease Xishai or direct sunlight and the glare: screen printing glass, due to the partial sequence of printing, right Xishai or direct sunlight a moderating role. Security: screen printing glass, an enhanced processing, increase the intensity of high security. Durability, wear resistance, moisture resistance: screen printing glass, the glass than the average pigment printing is more durable, abrasion resistance, moisture resistance. Applications:Exterior walls of glass, shops, homes, schools, window glass, interior compartment pattern glass, automotive glass, electrical glass, furniture and craft of glass, indoor non-slippery floors, staircases boards (subject to prior instructions). Kinds:

Specification:(Thickness:4~12mm)

|

|

|

|

|

| Ceramic Silkscreen Glazed Glass Standard Color Reference | |

|

|

| Applications: | |

|

|

Glass thermal transfer through 600 degrees of heat, by water, soft printing paper, copy its pattern through the heat of the way, the pattern on the transfer paper, a complete copy to the glass top.

Benefits:

Benefits: